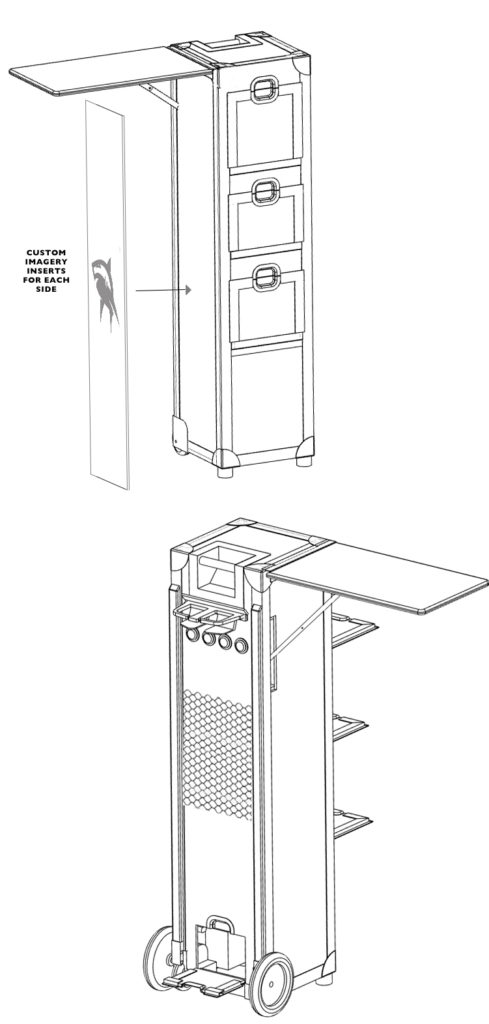

The Column Cooler can be fabricated in a variety of ways and styles. The different methods of construction are based on the Column Cooler’s intended use. Below are the different means of construction which can be further explored in the Concepts section of this site.

Paneled

Metal, plastic or composite frame system with plastic, wood or composite walls. Similar to the construction of entertainment industry road cases. External sleeve system allows for insertion of custom printed graphic skins.

Airframe/Caravan

Using internal rib structure (wood, metal, plastic, 3D printed) for the main body of the column, similar to an airplane or trailer design. The outer skin consists of one sheet, or sistered sheets, of a rigid material that is formed and secured around any open portions of the design (ie. doors, compartments or niches). That material, while traditionally aluminum in the personal caravan and airplane markets, could be composed of other metal, composites, plastics or wood. An internal sheet attaches to the inside of the rib system acting as an internal wall. The void in between the sheets is filled with an insulating material such as expandable or rigid foam. Doors are fabricated from either the body skin material or black/smoke tinted acrylic or tempered glass.

Rotomolding, Injection or Blow Molding

Inner and outer shells could be created offering a virtually seamless, durable, watertight design. The hollow void within the blown structure is filled with an insulating material such as expandable or rigid foam.

Sizing Options

Scaling of the design is easily achieved to fit the need of the consumer without the loss of overall functionality. From the hardcore tailgater, a family pick-nick or just a simple overnight outing – all the technology, function and convenience can be available in any size.

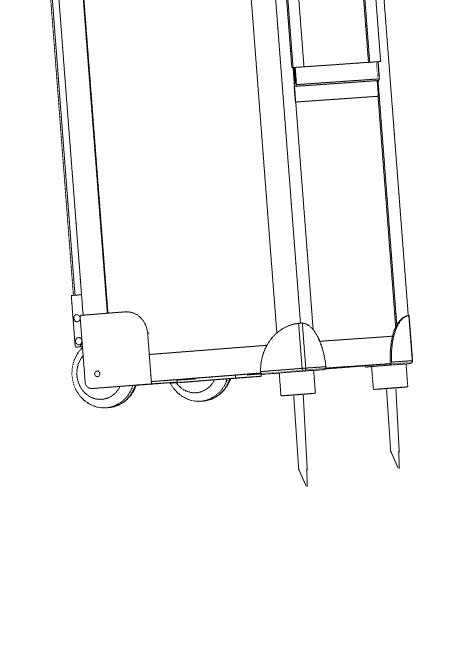

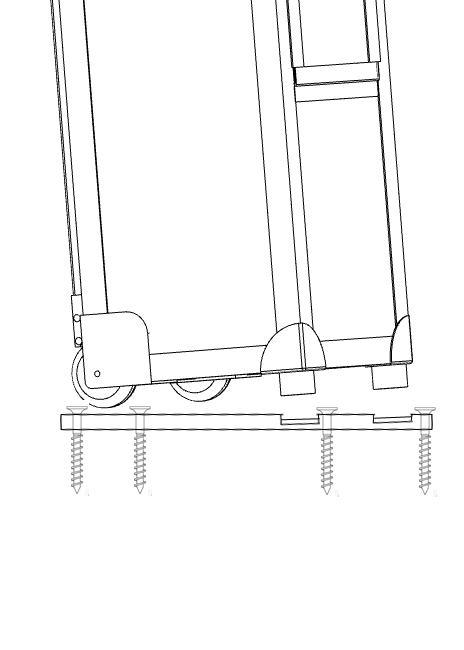

Mounting Options

Different snap in mounting options can be made available to add stability on rough/soft terrains or a permanently mounted base option for attaching to motor vehicles or boats.